Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

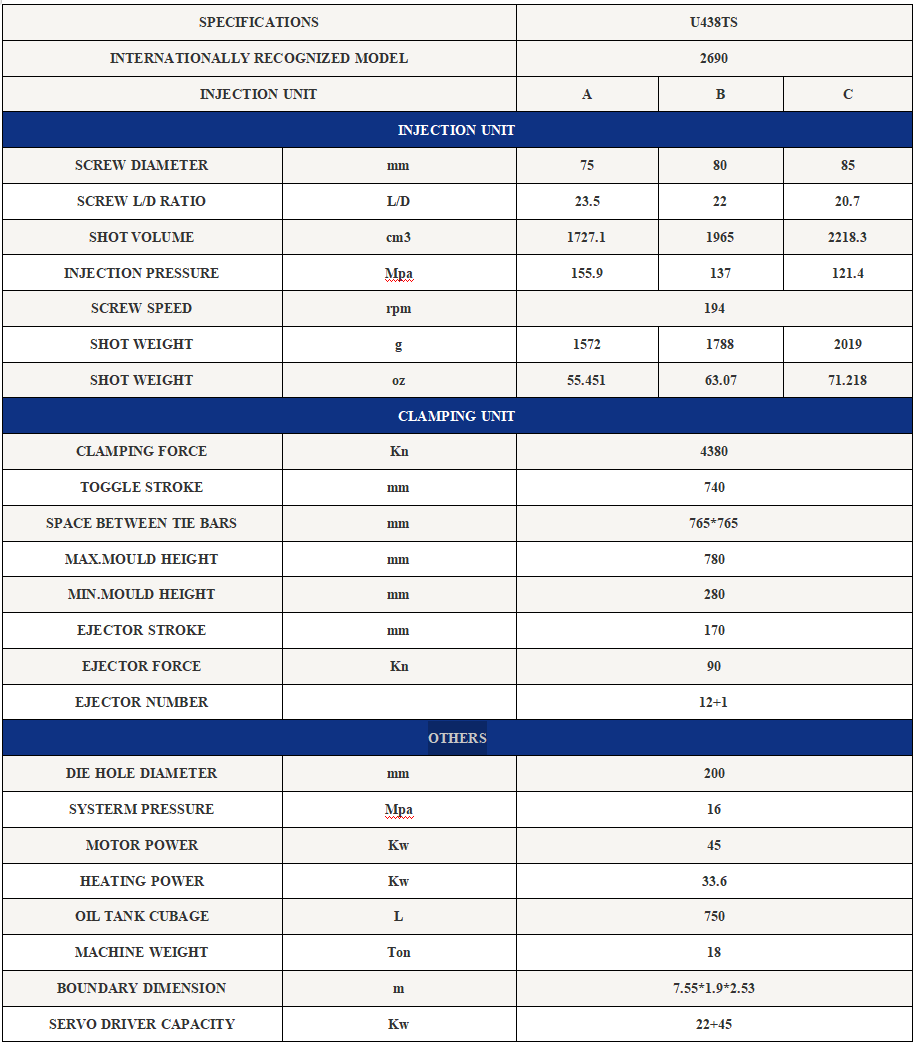

PET (scientific name polyethylene terephthalate) is widely used in: fibers, films, polyester bottles, etc. Due to the short stabilization time after the melting point and the high melting point, it is necessary to choose an injection system with more temperature control sections and less self-friction heat generation during plasticization, and the actual weight of the product should not be less than 2/3 of the injection volume of the machine.

The melt temperature can be measured by the air shot method. 270-295℃, the reinforced grade GF-PET can be set to 290-315℃, etc.; but after melting, the fluidity is good, so the craftsmanship is poor, and the anti-spreading device or mold is often added to the nozzle. flow device.

The injection speed is generally faster to prevent premature solidification during injection. But too fast, the high shear rate makes the material brittle. Shots are usually completed within 4 seconds.

The lower the back pressure the better to avoid wear. Generally not more than 100bar. Usually not needed.

Residence Time Do not use too long a residence time to prevent molecular weight drop. Try to avoid temperatures above 300°C. If the downtime is less than 15 minutes. It only needs to be air-shot; if it takes more than 15 minutes, it should be cleaned with viscosity PE, and the temperature of the barrel should be lowered to the PE temperature until it is turned on again.

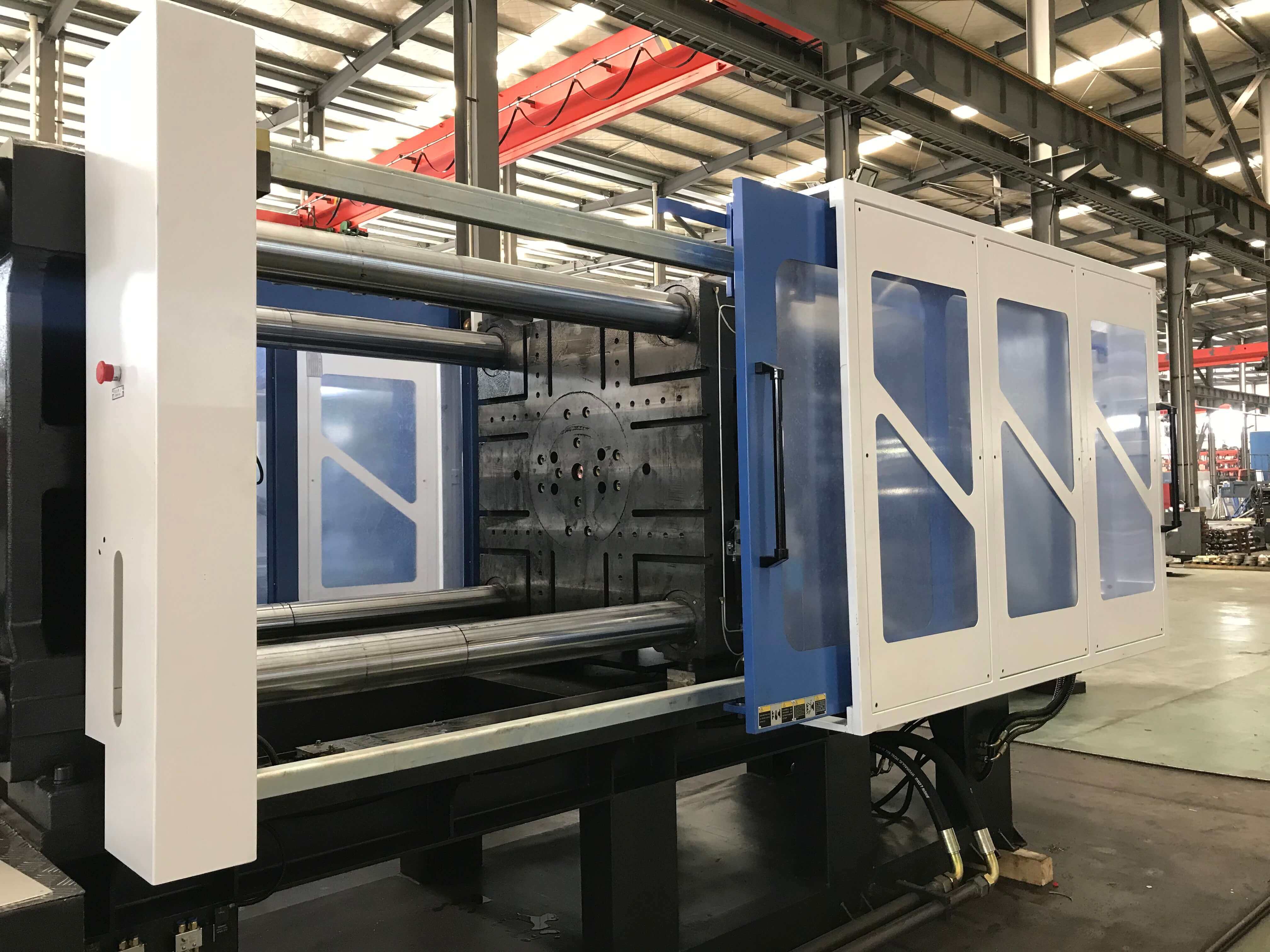

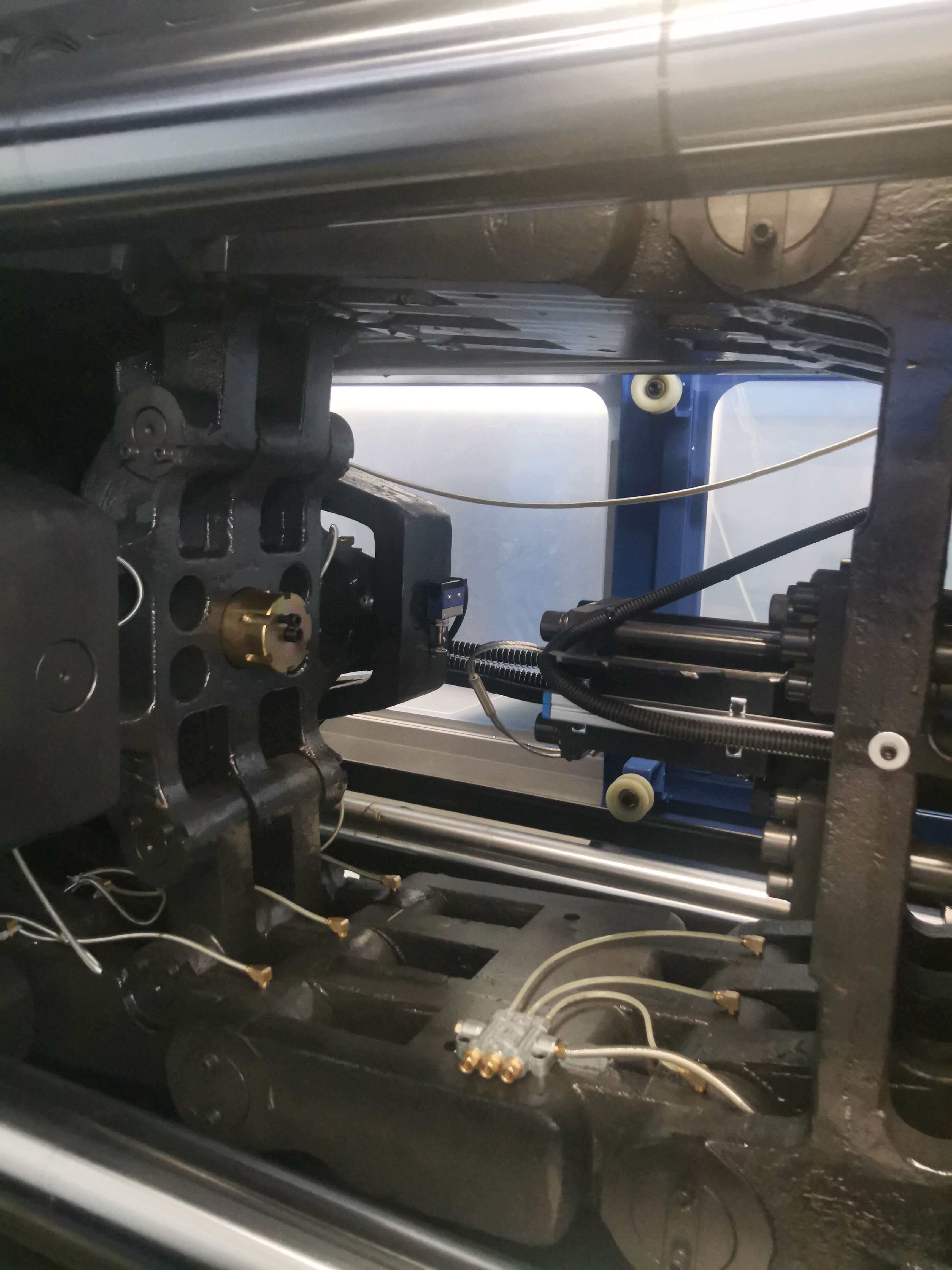

Based on these requirements, Sonly has designed a special machine for PET. According to the characteristics of PET plastic, the design structure of the material tube and screw has been changed, and the electronic control system, material storage system, hydraulic system, etc. are all different. Design changes; so as to meet customer requirements for PET products.

PET injection molding machine is one of the commonly used equipment in the plastic processing industry. Usually it has to work for a long time, and the molding cycle is short, and there are many plastic injections. Therefore, how to ensure the normal and stable operation of the injection molding machine in continuous production, regardless of the injection machine Manufacturers or users are a problem worthy of attention and efforts to solve, so regular preventive maintenance is an effective way to ensure the normal operation of the injection machine. The so-called preventive maintenance is a series of corrections and inspections to avoid machine failures, prolong the working life of various parts, and achieve normal andsmooth production.